Our Strengths

We turn 20+ years of ceramic expertise into reliable, ultra-precision solutions for global high-end industries.

What Makes Us Stand Out

-

✅

International Quality Assurance

We strictly adhere to ISO 9001:2015 standards — every ceramic component undergoes IQC/IPQC/OQC full-process inspection, ensuring quality meets world-leading benchmarks for laser semiconductor and aerospace customers. -

✅

Technological Innovation

We maintain deep partnerships with top institutions (Tsinghua University, Changsha University of Science and Technology) and operate an in-house R&D lab. Our team conducts comprehensive material analysis (microstructure, mechanical/electrical properties) to develop cutting-edge ceramics like high-toughness zirconia. -

✅

Tailored Custom Solutions

We develop specialized ceramic materials (e.g., silicon nitride for new energy vehicles) to meet unique customer requirements, helping industries like petrochemicals and medical devices overcome technical bottlenecks. -

✅

Global Market Presence

Our products are exported to 2000+ customers across 30+ countries/regions , with a dedicated office in Germany to provide localized support for European semiconductor and aerospace customers.

Authoritative Recognition

Our capabilities are validated by industry-leading standards:

- • ISO 9001:2015 Quality Management System Certification

- • 32 National Technical Patents (ceramic materials & precision machining)

- • "High-Tech Enterprise" Certification (China)

- • Preferred Supplier for Top 5 Global Semiconductor Equipment Manufacturers

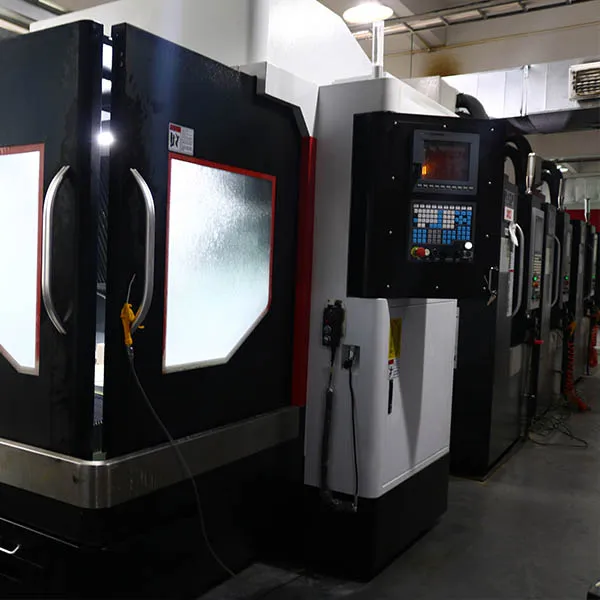

Advanced Precision Manufacturing

We possess internationally leading precision manufacturing equipment and technology to ensure high precision and consistency of products, meeting the stringent requirements of our customers.

Raw Material Preparation

We strictly control the selection and preparation process of raw materials to ensure product quality and performance stability from the source.

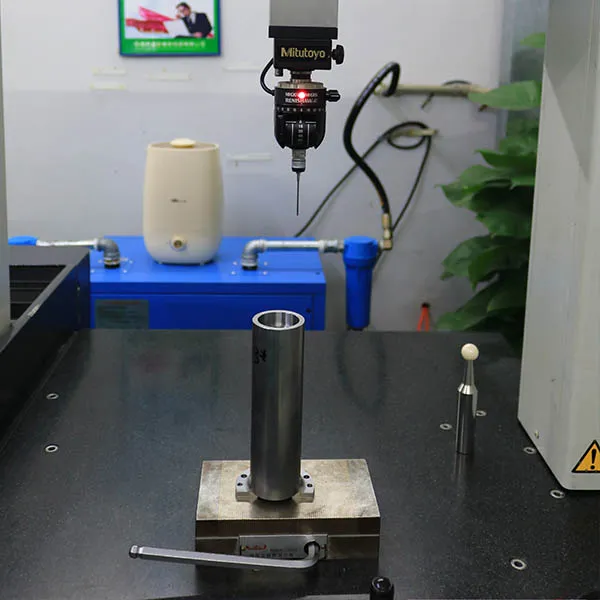

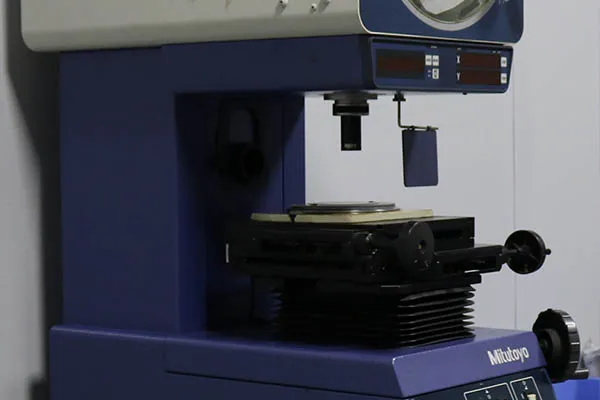

Precision Inspection

We are equipped with advanced testing equipment and a professional quality control team to ensure every product meets strict quality standards.

Laboratory with Advanced Material Testing Instruments

We are equipped with comprehensive testing equipment to ensure product quality and performance meet industry standards.

Zeiss 3D Measuring Machine

Dielectric Tester

Thermal Dilatometer

XRD X-ray Diffractometer

SEM Scanning Electron Microscope

Bending Strength Tester

Forming Equipment

We have a variety of advanced forming equipment to meet the manufacturing needs of different products.

Isostatic Press

Dry Press

Dry Press

Vertical Injection Molding Machine

Internal Mixer

Sintering Equipment

We are equipped with a variety of advanced sintering equipment to ensure high quality and performance stability of products.

Nitrogen Furnace

Vacuum Carbon Tube Furnace

Gas Pressure Sintering Furnace

Box Type Elevating Furnace

High Temperature Furnace

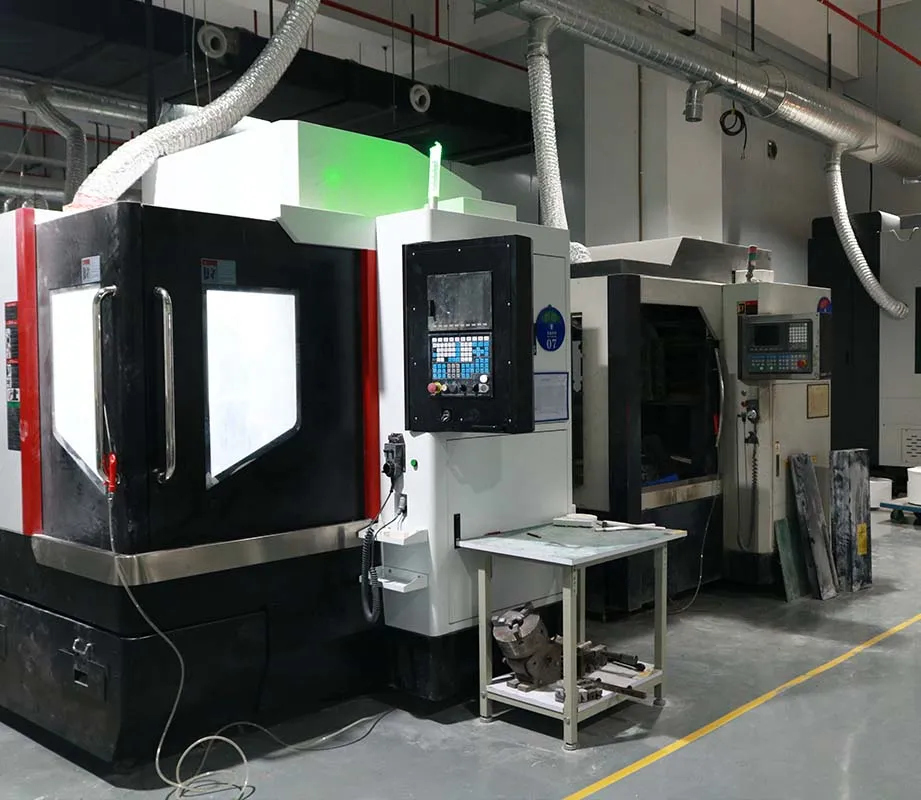

Precision Machining Equipment

We have advanced precision machining equipment to ensure high precision and surface quality of products.

CNC Grinding Machine

Cylindrical Grinder

AgieCharmilles Wire EDM

Optical Curve Grinder

5-Axis CNC Engraving Machine

Company Advantages

With years of industry experience and technical accumulation, XYC Ceramics has formed unique competitive advantages in the field of advanced ceramics.

R&D Capabilities

The company has renowned professors and doctors in the ceramic materials industry, more than 30 professional personnel, and strong R&D support from research institutes and university-enterprise cooperation.

Powder Formulation

With multiple material doctors and rich application case experience, we can develop formulations according to customer needs to meet their requirements.

Forming & Sintering

Equipped with various forming and sintering equipment, we can perform corresponding forming and sintering according to different material requirements.

Precision Machining Capabilities

With more than 20 years of accumulated precision machining experience and complete processing equipment for various processes, we can provide customized solutions according to customer requirements in depth.

High-Quality Assurance

The company has IQC, IPQC, and OQC departments, and multiple high-precision testing equipment to strictly control quality, meeting various industry standard testing requirements.

Complete Industrial Chain

The company has a complete closed-loop industrial chain, from formulation → forming → sintering → precision manufacturing → high-cleanliness surface treatment → solution testing, all completed by our company.

Ready to Start Your Project?

Contact us to learn how XYC Ceramics can provide high-quality advanced ceramic solutions for your business