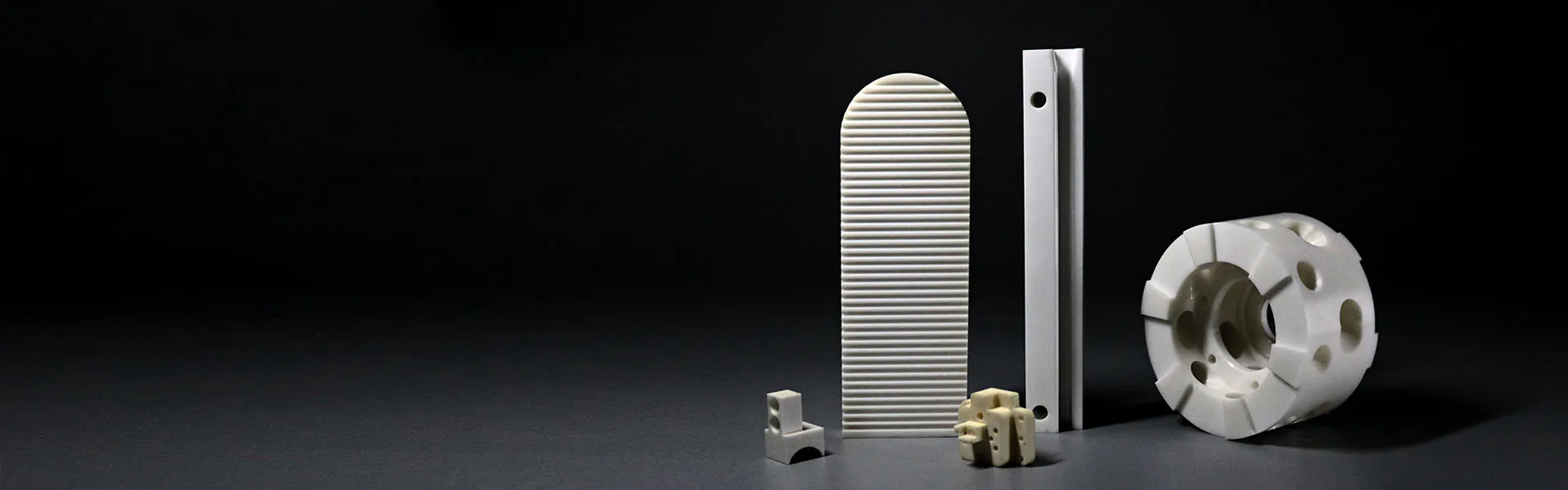

Professional Custom Parts

One-stop Solution from Sample to Mass Production

Precision Manufacturing

Tolerance Control ±0.001mm

Premium Materials

Multiple High-Performance Materials Available

Rapid Response

Sample Delivery Within 72 Hours

Non-disclosure Agreement Available

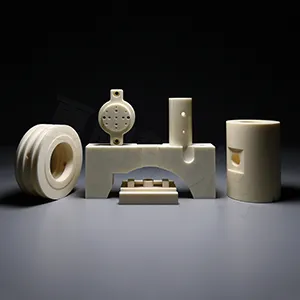

Advanced Ceramics Series

We provide a variety of high-performance ceramic materials to meet the special needs of different industries

Alumina Ceramic

Alumina ceramic is the most widely used advanced ceramic material, featuring high strength, high hardness, high temperature resistance, wear resistance, and good insulation properties. According to different alumina content, it can be divided into multiple grades such as 97%, 99.5%, and 99.7% alumina ceramics.

Key Features:

- High hardness HRA90 ~ 93

- Excellent resistivity (1X10)/span>

-

Medium to super high mechanical strength (360-600 MPa)

Extremely high compressive strength (2250-2700 N/mm²)

Low thermal conductivity (25-32W/MK)

The maximum operating temperature is 1200° C.

Zirconia Ceramic

Zirconia ceramic is a high-performance structural ceramic with extremely high fracture toughness and bending strength, while also having excellent wear resistance and biocompatibility. Stabilized zirconia ceramic can remain stable over a wide temperature range.

Key Features:

- Extremely high toughness 6-10 MPam1/2

- Excellent heat insulation/low thermal conductivity (3W/MK)

-

Maximum operating temperature 1000℃

Excellent chemical stability

High thermal expansion performance (A=10X10-6/K, close to steel)

Silicon Nitride Ceramic (Si3N4)

Silicon nitride ceramic is a high-performance structural ceramic with excellent properties such as high strength, high hardness, high temperature resistance, oxidation resistance, and corrosion resistance. It also has good insulation and thermal conductivity, making it an ideal material for extreme environments.

Key Features:

- Extremely high hardness (92.5HRA)

- Good bending strength (850 MPa)

-

Very low density (3.20g/cm³)

Excellent fracture toughness (6 ~ 7.0 MPam 1/2)

Very low coefficient of thermal expansion(3.2X10-6/K)

Maximum operating temperature :1400℃

Silicon Carbide Ceramic

Silicon carbide is almost like diamonds. It is not only the lightest, but also the hardest ceramic material, with excellent thermal conductivity, low thermal expansion, very resistant to acid and alkali, and does not crack easily in hot and cold environments. So silicon carbide is excellent kiln materials, furnace materials, high temperature damage resistance parts. The excellent resistance of SIC to corrosion, wear and erosion is as good as its ability to withstand friction and wear.

Key Features:

- Very low density (3.20g/cm³)

- Extremely high hardness: (94 HRA)

-

High heat conductivity (8 0W/ MK)

Low expansion coefficient (4.5 ×10-6 / K,400℃)

Maximum operating temperature: 1600℃

Good corrosion and wear resistance at high temperature

Magnesium Zirconium Ceramics

Magnesium Zirconium Ceramics is a high-performance structural ceramic based on zirconia with magnesium oxide (MgO) as a stabilizer, featuring excellent fracture toughness, thermal shock resistance, and high-temperature stability. It maintains high strength while exhibiting good anti-aging properties, suitable for key components in harsh working conditions.

Key Features:

- High fracture toughness, excellent impact resistance

- Good thermal shock resistance, suitable for rapid temperature change environments

- Structurally stable at high temperatures, corrosion and wear resistant

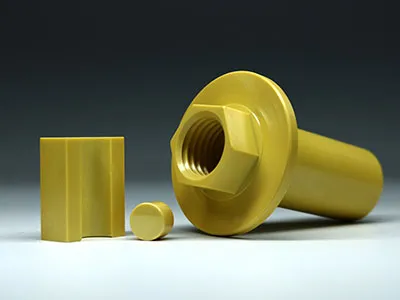

Tungsten Steel Custom Parts

Tungsten steel (carbide) is a high-performance composite material with tungsten carbide as the main component and cobalt or other metals as the binder phase. It has extremely high hardness, excellent wear resistance, compressive strength, and good dimensional stability. We provide high-precision, complex structure tungsten steel custom parts, widely used in molds, cutting tools, mining tools, precision machinery and other fields.

Key Features:

- High hardness up to HRA 86–93, excellent wear resistance

- High compressive strength, suitable for high-load working conditions

- Can be precision machined, supporting complex geometric shape customization

Core Processing Capabilities

Focused on high-precision advanced ceramic manufacturing, providing full-process industrial ceramic solutions from material selection to finished product delivery

Providing Complete Advanced Ceramic Technology Solutions

Equipped with precision processing capabilities for various ceramic materials such as alumina, zirconia, and silicon nitride, with processing accuracy up to ±0.001mm and surface roughness Ra≤0.02μm.

- One-stop ceramic solutions

- Full-process service from design to mass production

- Meeting high-demand scenarios in medical/electronics/aerospace

Precision Tungsten Steel Processing

Specialized in processing various grades of tungsten steel materials, equipped with high-end equipment such as 5-axis machining centers, capable of processing complex-shaped tungsten steel parts with hardness up to HRC90+.

- Precision forming solutions for super hard materials

- Micron-level precision control technology

- Customized cutting tool/mold solutions

Advanced Ceramic Component Customization

Capable of producing metal and industrial ceramic components, with an annual output of over 5 million precision components, serving 500+ global customers.

- Multi-material integrated manufacturing solutions

- Balancing mass production and small-batch customization

- Full-dimension inspection and quality traceability system

Precision Finishing

Equipped with imported high-precision grinders, capable of plane, internal/external cylindrical, and profile grinding, with accuracy up to 0.0005mm, providing mirror grinding services.

CNC Turning Processing

Equipped with multiple high-precision CNC lathes, capable of processing various rotating parts, supporting automatic feeding, realizing efficient mass production, and ensuring dimensional consistency.

Advanced Ceramic Processing

Focused on precision processing of high-hardness, high-brittleness advanced ceramics, including plane grinding, external cylindrical grinding, CNC milling, and laser cutting, with dimensional accuracy up to ±0.005mm, meeting strict industrial application requirements.

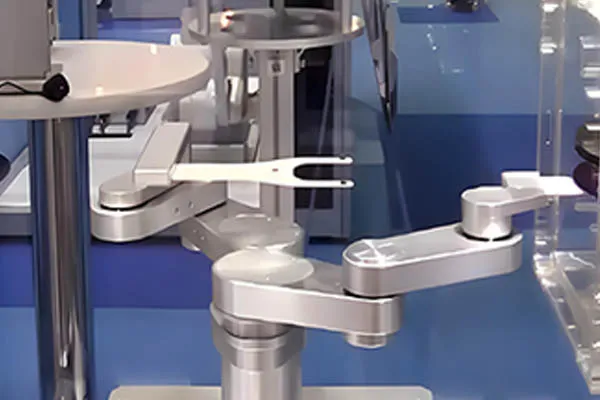

Assembly and Testing

Providing one-stop services for component assembly, performance testing, and reliability verification, equipped with professional testing equipment to ensure products meet customer requirements.

About XYC Custom Advanced Ceramics Manufacturer

20 years focused on advanced ceramic R&D and production, providing high-quality ceramic products and solutions to global customers

50000+

Production Base (㎡)

8000000+

Annual Production Capacity (pcs)

30+

Export Countries

500+

Global Customers

Visit XYC Ceramics

Learn about our production bases, R&D strength and advanced manufacturing processes through videos

Product Center

We provide a variety of high-performance ceramic materials and products to meet the special needs of different industries

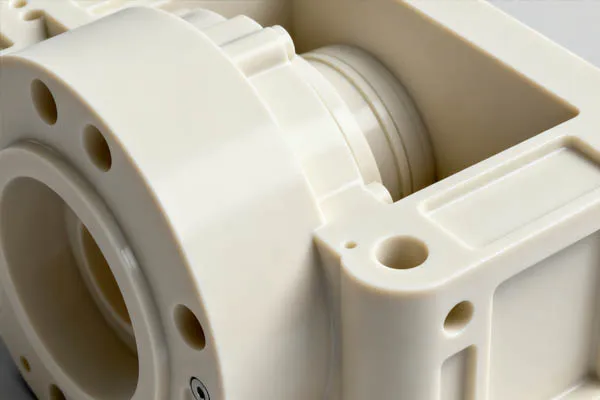

Custom Ceramic Products

Provide customized ceramic product development and production according to customer needs, meeting special working condition requirements.

Ceramic Pump and Valve Plunger

Made of toughened structural ceramic materials, high mechanical strength, long service life With wear resistance, corrosion resistance, high temperature stability,chemical...

Welding Roller

*Material has high hardness, high temperature resistance, and excellent thermal shock stability *High bending and compressive strength *Surface profile accuracy...

Ceramic Roller-ceramic Dual-roll-ceramic Three-roll

*Material has high hardness, high wear resistance, non-magnetic and non-conductive. *Exceptional thermal stability and maintains its performance even underhigh-temperature working...

Powder Equipment Accessories

High temperature resistance, acid and alkali corrosion resistance High hardness and good wear resistance Good chemical stability, less likely to...

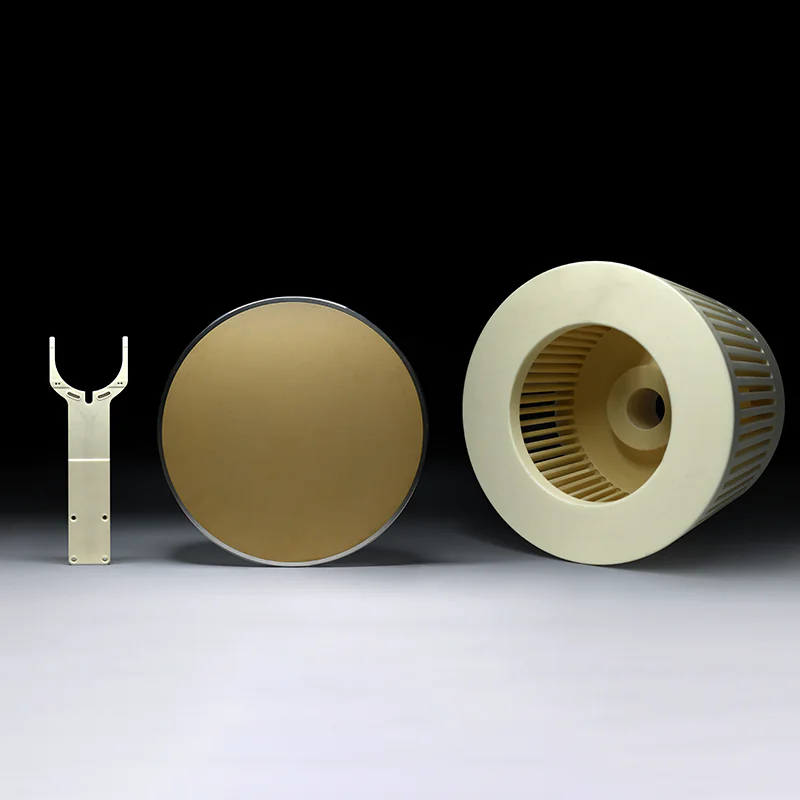

Semiconductor Equipment Parts

Excellent wear resistance, high temperature resistance, corrosion resistance, thermal shock resistance,insulation and other characteristics Good price compared with traditional materials,...

Precision Ceramic Parts

Can do special shaped fine processing, range can be up to 250mm X 200mm X 200mm The precision can reach...

Tungsten Carbide Parts

Tung.sten carbide has excellent properties such as abrasion resistance, corrosion resistance and hiehtemperature resistance, and is increasingly used in various...

Our Manufacturing Capabilities

Advanced production equipment and processes ensure the provision of high-quality ceramic products to customers

Advanced Production Processes

XYC has a complete advanced ceramic production line, from raw material preparation to finished product processing, with strict control over every process to ensure stable and reliable product quality.

Raw Material Preparation

Selection of high-purity raw materials and precise proportioning, ensuring material performance consistency, with particle size control up to sub-micron level.

Forming Technology

Multiple forming methods including dry pressing, isostatic pressing, and injection molding, capable of producing complex-shaped products.

Sintering Process

Imported atmosphere sintering furnace with temperature control precision of ±1℃, capable of achieving high-temperature sintering up to 1800℃.

Precision Machining

Using diamond grinding wheel and laser processing technology, achieving machining precision of ±0.001mm to meet high-precision requirements.

Strict Quality Control

Raw Material Inspection

Strict inspection of each batch of raw materials to ensure purity, particle size and other indicators meet requirements, controlling product quality from the source.

Process Control

Real-time monitoring of key parameters during production, with strict quality inspection at each process to ensure production stability.

Finished Product Testing

Comprehensive testing of finished products including size, density, hardness, strength, etc., ensuring every product meets customer requirements.

Application Areas

Our advanced ceramic products are widely used in multiple industrial fields

Electronics & Semiconductors

Ceramic substrates, insulators, packaging materials, etc., meeting the high temperature, high insulation, and high thermal conductivity requirements of electronic devices.

Learn More Semiconductor industry

Medical Devices

Biocompatible ceramic materials used in medical devices, artificial joints, dental materials, etc., safe and reliable.

Learn More Food and medical industry

Automotive Industry

Ceramic bearings, sensors, wear-resistant components, etc., applied in new energy vehicles to improve efficiency and reliability.

Learn More Automotive Industry

Precision Machinery

High-precision ceramic structural components, guide rails, bearings, etc., providing excellent wear resistance and stability.

Learn More Precision machinery industry

New Energy

Ceramic insulation materials, wear-resistant components applied in photovoltaic, wind power, energy storage and other new energy equipment.

Learn More New energy vehicle industry

Tungsten Steel Custom Parts

High-performance tungsten steel components play an important role in various fields with their excellent hardness and wear resistance. They are widely used in key parts, precision mechanical components and high-strength structural parts to ensure stable operation of equipment under extreme conditions.

Learn MoreCustomer Cases

We cooperate with leading enterprises in various industries to provide high-quality ceramic material solutions

Semiconductor Equipment Ceramic Component Solutions

Provided high-precision alumina ceramic components for a well-known semiconductor equipment manufacturer, increasing equipment service life by more than 30%.

View Details

Medical Equipment Zirconia Ceramic Components

Developed biocompatible zirconia ceramic components for medical device enterprises, meeting medical-grade material requirements and applied in various high-end medical equipment.

View Details

New Energy Vehicle Motor Ceramic Bearings

Provided high-performance silicon nitride ceramic bearings for new energy vehicle manufacturers, improving motor efficiency, reducing energy consumption, and extending service life.

View DetailsCustomer Reviews

Genuine reviews from customers in various industries about our products and services

"The alumina ceramic components provided by XYC have very stable quality and high dimensional accuracy, which has improved our production efficiency by 20%. Their technical support is also very professional and can quickly respond to our needs."

Director Zhang

An electronic equipment manufacturer

"As a medical device enterprise, we have very high requirements for materials. The zirconia ceramic products from XYC fully meet our quality standards, with good biocompatibility and high processing precision, making them our reliable partner."

Manager Li

A medical device company

"We adopted silicon nitride ceramic bearings from XYC in our new energy vehicle motors, which not only improved motor efficiency but also greatly reduced failure rates. Their customization service is also very professional and can quickly provide solutions according to our needs."

Engineer Wang

An automobile manufacturing enterprise

Contact Us

No matter what questions or needs you have, our professional team will provide you with timely and professional services

Send Inquiry

Contact Us

Need Custom Advanced Ceramic Products?

We have a professional R&D team and advanced production equipment, capable of customizing various high-performance ceramic products according to your needs. Welcome to contact us at any time.