先进陶瓷快速成型技术:开启多领域创新的尖端技术

Introduction: Advanced ceramic materials inherently possess advantages such as high temperature resistance, corrosion resistance, and good biocompatibility. Additive manufacturing technology (commonly known as 3D printing) breaks the limitations of traditional manufacturing, enabling more flexible design. When these two are combined, advanced ceramic 3D printing technology has unlocked applications in multiple key fields—from healthcare to aerospace, from electronic products to military equipment—and its range of uses continues to expand. Today, the global market for this technology is growing steadily at an annual rate of 7% to 9%, quietly driving the upgrading and transformation of various industries.

I. Biomedical Field: A “Personalized Expert” for Customized Healthcare

The core requirements for medical materials are safety, stability, and precise fit to each individual’s body. The personalized customization capability of advanced ceramic 3D printing has opened a new door for innovations in medical devices. For example, ceramic teeth made via 3D printing, after high-temperature treatment at 1500℃, have strength fully meeting international medical standards—they fit the shape of teeth and are durable. Currently, they are widely used in dentistry at many major hospitals in China, having helped over 100,000 people restore their teeth and greatly improving dental treatment efficiency. Additionally, bionic ceramic bone repair scaffolds designed to mimic the internal structure of loofah sponges, after rigorous safety tests and animal experiments, have been used in research on repairing femoral head necrosis in humans, effectively aiding bone growth and healing. Furthermore, an absorbable composite ceramic scaffold is being piloted in the treatment of congenital bone defects in children, providing a more flexible new option for bone regeneration therapy.

II. Electronic Components Field: A Core Helper for “Small Size, Great Power”

Today’s electronic products are becoming smaller, lighter, and more powerful, making it difficult for traditional manufacturing processes to produce such complex precision components. The high precision and high integration advantages of advanced ceramic 3D printing make it an excellent helper in the electronic field. For instance, small antenna arrays made of ceramic via 3D printing have been mass-produced and used in communication modules of 5G base stations. They not only reduce the weight of communication systems and speed up assembly but also improve communication performance and lower costs. Signal filters made of special ceramics perform exceptionally well and have been integrated into the communication equipment of the Beidou-3 Satellite Navigation System, serving as core components for high-end communications. Moreover, ceramic substrates with optimized structures via 3D printing have been successfully applied in power modules of new energy vehicles, significantly enhancing insulation and heat resistance, and making electronic products more reliable with better performance.

III. Aerospace Field: A “Reliable Guardian” for Extreme Environments

The aerospace field has extremely strict requirements for materials: they must be high temperature resistant, lightweight, durable, and able to withstand extreme space environments. Advanced ceramic 3D printing technology perfectly meets these high demands. For example, a double-layer protective structure made of ceramic composite materials via 3D printing has been used on the outer layer of a certain type of spacecraft—the inner ceramic layer stabilizes the internal temperature, while the outer layer efficiently absorbs microwaves, making it perfectly suitable for space environments. A type of special ceramic, due to its high hardness, good thermal conductivity, and low thermal deformation, has become the preferred material for large-diameter, lightweight space telescopes and their support structures. The ceramic support structure made via 3D printing has been successfully installed on a Chinese deep-space exploration satellite, solving the manufacturing challenge of large and complex ceramic components at once. Additionally, the combustion chamber lining of an aero-engine made using this technology has successfully passed test runs on a certain type of aero-engine prototype. It not only speeds up production but also improves reliability, providing strong support for the upgrading of aero-engines, spacecraft, and other national key equipment.

IV. Machinery and Processing Field: A “Hardcore Partner” for High Efficiency and Wear Resistance

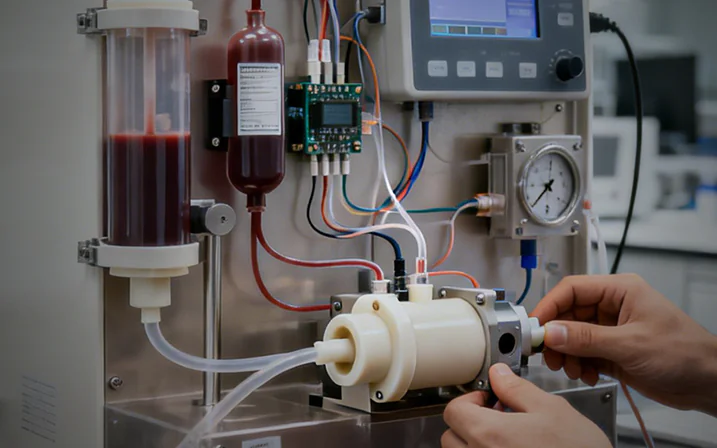

In the machinery processing industry, the hardness, wear resistance, and high temperature resistance of components directly affect the service life and work efficiency of equipment. Parts made via advanced ceramic 3D printing have become ideal partners in the industry thanks to these advantages. For example, ceramic cutting tools made via 3D printing have high hardness and good toughness, and have been used in high-speed cutting production lines for aluminum alloy cylinder blocks of automobile engines—their processing efficiency is over 30% higher than that of traditional metal tools. Ceramic seals, bearings, and other components, due to their impact resistance and corrosion resistance, are widely used in high-temperature and high-pressure pumps in the petrochemical industry, accounting for 10% of the advanced ceramic application market. Data shows that wear-resistant and corrosion-resistant ceramic parts account for as much as 33.4% of applications in the machinery field. For example, 3D-printed ceramic wear-resistant liners installed on conveying equipment of mining machinery have a service life more than 5 times longer than traditional metal liners. They can greatly reduce equipment wear, improve production efficiency, and help the machinery manufacturing industry develop in a more efficient and energy-saving direction.

V. National Defense and Military Field: A “Customization Tool” for Special Needs

Special equipment in national defense and military fields has extremely high requirements for customized and high-performance materials and components. Advanced ceramic 3D printing technology provides a new solution for these special needs. For example, bulletproof ceramics—composite bulletproof ceramic plates made via 3D printing have been mass-produced and equipped on a certain type of individual body armor in China. They can effectively resist 7.62mm armor-piercing bullets while being 40% lighter than traditional steel protective plates, serving as a hardcore shield for individual protection and accounting for 2.57% of relevant applications. Special transparent ceramics for national defense, which can be formed into complex curved shapes via 3D printing, have been used in the optical windows of a certain type of laser-guided weapon. They provide key optical support for laser weapons, radar systems, and other equipment, ensuring precise operation even in complex environments. Furthermore, aero-engine turbine guide vanes made of ceramic composite materials via 3D printing have completed ground bench tests on a certain type of military aero-engine. They are high temperature resistant and impact resistant, supporting the high-performance upgrading of military equipment and further enhancing China’s national defense science and technology strength.

Conclusion: From healthcare equipment that safeguards health to military equipment that defends the country, from core components that make electronic products more advanced to mechanical parts that improve production efficiency, the application scope of advanced ceramic 3D printing technology continues to expand, becoming a valuable helper for technological innovation in various industries. In the future, as technology matures further, it will play a greater role in more fields, continuously contributing to the high-quality development of the national economy and the technological security of key national fields.