Führende internationale und inländische Unternehmen der Industriekeramik

The advanced ceramics and industrial ceramics sectors are experiencing dual opportunities from technological breakthroughs and market expansion, with Chinese companies achieving import substitution in several niche areas. As one of the few domestic manufacturers with full-industry-chain capabilities, XY Ceramics has become a key supplier in high-end fields such as semiconductors and medical devices, leveraging its strengths in materials R&D and precision manufacturing.

Internationale Giganten dominieren mit starken technologischen Monopolen

Japans Kyocera employs a vertically integrated strategy spanning seven major fields, including semiconductor components and medical artificial joints, and holds a global market share of over 30% in LED sapphire substrates.

Germany’s CeramTec dominiert den Weltmarkt für keramische Komponenten in künstlichen Hüftgelenken mit einem Anteil von mehr als 90%; sein Biolox®. Serie ist mit einer extrem niedrigen Verschleißrate von 0,001 mm/Jahr ein Maßstab für die Branche. Diese Unternehmen haben durch firmeneigene Materialrezepturen (z. B. die ZTA-Nanokomposit-Keramik von CeramTec) und Präzisionsbearbeitungsverfahren (mit einer Oberflächenrauheit von <0,02 μm) erhebliche technologische Barrieren aufgebaut.

Einheimische Unternehmen beschleunigen die Lokalisierung und Importsubstitution

Sanhuan-Gruppe steht weltweit an erster Stelle bei den Marktanteilen für keramische Ferrulen für optische Fasern und keramische Verpackungssubstrate (PKG). Im ersten Halbjahr 2025 verzeichnete das Unternehmen einen Umsatz von 4,149 Mrd. RMB, wobei seine vertikal integrierten Prozesse eine vollständige Kontrolle vom Pulver bis zum fertigen Produkt ermöglichen.

Guoci-Materialien hat die ausländischen Monopole bei Zirkonoxidkeramik und thermoelektrischen Kühlern (TECs) gebrochen und im ersten Halbjahr 2025 einen Nettogewinn von 332 Millionen RMB erzielt. Yixing Guangming Spezial-Keramikmit einer Maßgenauigkeit von ±0,001 mm hat sich zu einem Lieferanten von keramischen Präzisionskomponenten für Unternehmen wie Siemens und Cummins entwickelt.

XY Ceramics: A Technological Trailblazer with Full-Industry-Chain Layout

Unternehmenspositionierung und Kernkompetenzen

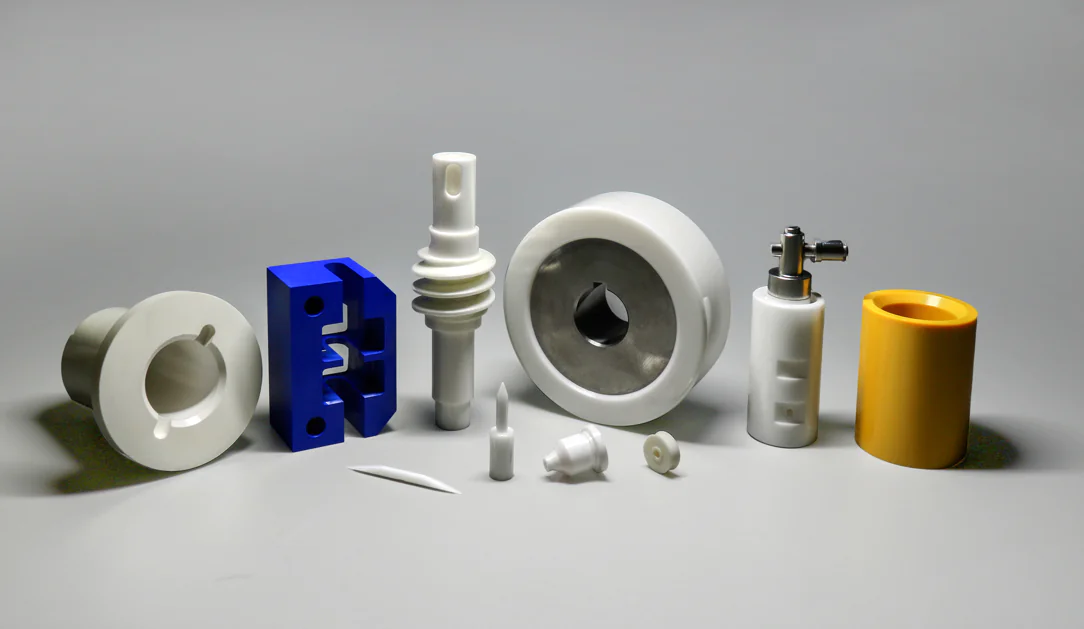

Dongguan XY Advanced Materials Co., Ltd. (“XY Ceramics”) is one of the few domestic manufacturers covering the entire industrial chain from powder formulation to precision manufacturing. Its product portfolio spans six major material systems, including zirconia, alumina, silicon nitride, and silicon carbide, serving high-end applications in semiconductors, medical devices, and new energy.

The company operates a Guangdong Provincial Key Laboratory and is equipped with advanced equipment such as gas-pressure sintering furnaces and cold isostatic presses, enabling the production of complex structural parts with dimensional accuracy of ±0.005 mm.

Technologische Durchbrüche und Produktvorteile

- Werkstoff-Innovation: Independently developed magnesia-stabilized zirconia (Mg-PSZ) addresses the phase-transformation issues of traditional yttria-stabilized zirconia in high-temperature and humid environments. With a flexural strength of 1200 MPa and excellent chemical stability, it is now used in volume production for petrochemical seals.

- Fortschrittliche Fertigung: Combining 3D printing with isostatic pressing, the company can produce elongated ceramic parts up to 2000 mm in length, with density uniformity controlled within ±0.02 g/cm³ and a defect rate below 0.5%.

- Highlights der Anwendung: Keramiksubstrate aus Aluminiumnitrid (AlN) für Halbleitergeräte erreichen eine Wärmeleitfähigkeit von 170 W/(m-K); Zahnersatz aus medizinischem Zirkoniumdioxid bietet eine Präzision von 0,1 μm; und Lager aus Siliziumnitrid für Motoren von Fahrzeugen mit neuer Energie erreichen Drehzahlen von mehr als 15.000 U/min.

Marktgestaltung und Zukunftspläne

Currently, 65% of XY Ceramics’ revenue comes from the domestic market and 35% from exports to Europe, with customers including a leading semiconductor equipment manufacturer and medical device companies. After securing tens of millions RMB in funding in 2025, the company plans to expand into the Japanese and South Korean markets and increase R&D investment in silicon carbide ceramics for aero-engine applications. Its ceramic heating plates have already entered the lithography machine supply chain, breaking foreign monopolies.

Branchentrends und Herausforderungen

Der globale Markt für Industriekeramik wird voraussichtlich ein Volumen von 646 Milliarden USD bis 2030, with China’s localization rate rising from 5% in 2015 to 25% in 2025. However, high-end powders (such as silicon nitride powder with 99.99% purity) still rely on imports, and 30% of key processing equipment must be sourced from Germany and Japan.

Companies like XY Ceramics are narrowing the gap with international leaders through industry-university-research collaboration (e.g., joint development of nanocomposite ceramics with Tsinghua University). Looking ahead, driven by AI-enabled smart manufacturing and the adoption of green sintering processes, the industry will shift toward “customized materials + intelligent manufacturing.”

The essence of competition in advanced ceramics lies in material formulations and process precision. XY Ceramics’ path to breakthrough demonstrates that Chinese enterprises can rise from “participants” to “rule-makers” in the global industrial chain by achieving sustained progress in “chokepoint” areas such as powder R&D and precision machining.