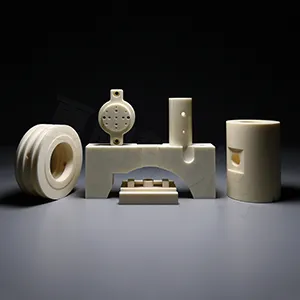

Processing & Material Capabilities

We are equipped with an industry-leading cluster of processing equipment, integrating R&D, sintering, and machining, to ensure 0.005mm-level ultra-precision quality and stable mass production delivery.

Core Processing Equipment

We are equipped with an industry-leading cluster of processing equipment, covering the entire production process of advanced ceramics, to meet the diverse customization needs of global customers:

5-axis CNC machining centers

Realize integrated processing of complex-shaped ceramic components, ensuring high precision and efficiency

Pressure/vacuum sintering furnaces

Adapt to the sintering process requirements of different ceramic materials, improving material density and performance

Optical curve grinding machines

Meet micron-level dimensional accuracy requirements, ensuring the consistency of component sizes

Mirror EDM machines

Guarantee the surface finish of ceramic components, suitable for high-end precision application scenarios

Advanced Materials Portfolio

High-performance Advanced Ceramic & Tungsten Carbide Materials

We provide a full range of high-performance advanced ceramic and tungsten carbide materials, with complete specifications and stable performance, widely used in semiconductor, new energy vehicle, aerospace, medical, and other high-end industries.

Unser Unternehmen kann einige spezielle Hochleistungskeramiken entsprechend den Kundenanforderungen anpassen.

Wir heißen auch Universitäten und Forschungsinstitute herzlich willkommen, mit uns zusammenzuarbeiten.

Toughened Zirconia (ZrO₂)

High wear resistance, excellent insulation, good biocompatibility;

Suitable for new energy vehicle battery insulation parts, medical surgical instruments, food-grade cutting tools.

High-Purity Alumina (Al₂O₃)

High temperature resistance (≤1700℃), strong corrosion resistance, good mechanical strength;

Suitable for semiconductor equipment fixtures, petrochemical corrosion-resistant valves, industrial wear parts.

Silicon Nitride (Si₃N₄)

High strength, excellent thermal shock resistance (-50℃~1200℃), good lubricity;

Suitable for aerospace sensors, new energy vehicle powertrain components, high-speed mechanical parts.

Siliziumkarbid (SiC)

Ultra-high temperature resistance (≤1600℃), high thermal conductivity, strong oxidation resistance;

Suitable for high-power electronic component heat dissipation parts, industrial high-temperature furnace core components, petrochemical equipment.

Aluminum Nitride (AlN)

Excellent electrical insulation, high thermal conductivity (≥180W/m·K);

Suitable for semiconductor chip heat dissipation substrates, 5G communication equipment thermal conductive parts, electronic packaging components.

Tungsten Carbide (WC)

Ultra-high hardness (HRA86~93), excellent wear resistance, high temperature stability (hardness at 500℃);

Suitable for precision cutting tools, petrochemical valves, cold work molds, geological exploration bits, industrial wear-resistant structural parts.

Halbleiter-Keramik-Produktkoffer

Entdecken Sie unsere anderen keramischen Hochleistungsprodukte, die für die Halbleiterindustrie entwickelt wurden, um die Anforderungen verschiedener Anwendungsszenarien zu erfüllen

Alumina ceramic wafer chuck with warpage less than 0.05mm, mechanical ceramic arm, handling ceramic arm

High-Precision Alumina Ceramic Components for Advanced Semiconductor Manufacturing 1. Alumina...

Mehr erfahren

Alumina Ceramic Microporous Chuck | Semiconductor Wafer & Chip | Vacuum Chuck | Wear-Resistant Porous Ceramic

Product Description Alumina Ceramic Microporous Chuck | Semiconductor Wafer &...

Mehr erfahren

Silicon nitride ceramic substrate | 6-inch plate CNC processing | Semiconductor

High temperature resistance, acid and alkali corrosion resistance High hardness...

Mehr erfahrenKontakt

Wenn Sie weitere Informationen über Werkstoffe für Präzisionsinstrumente oder kundenspezifische Anforderungen wünschen, füllen Sie bitte das nachstehende Formular aus. Unser professionelles Team wird sich dann so schnell wie möglich mit Ihnen in Verbindung setzen.

Adresse des Unternehmens

Nr. 28, Xiangkou Road, Huangnitang Industrial Park, Changping Town, Dongguan City, Guangdong, China

Kontakt Telefon

+86-769-83939973

E-Mail Adresse

mag2@xycarbide.com

Arbeitszeiten

Montag bis Freitag: 9:00 - 18:00