Client Cases

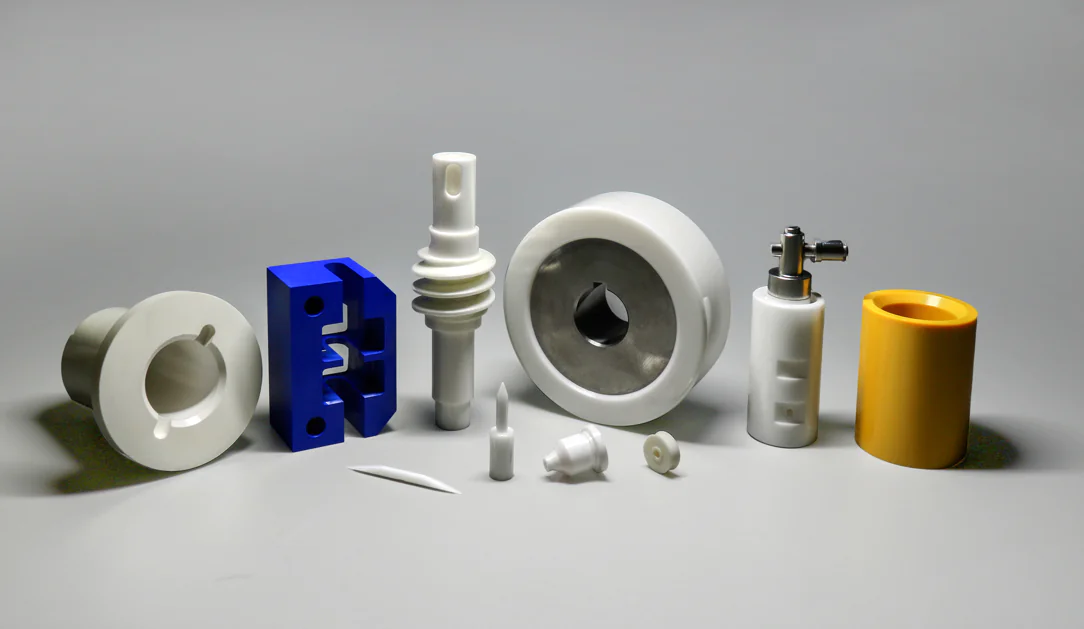

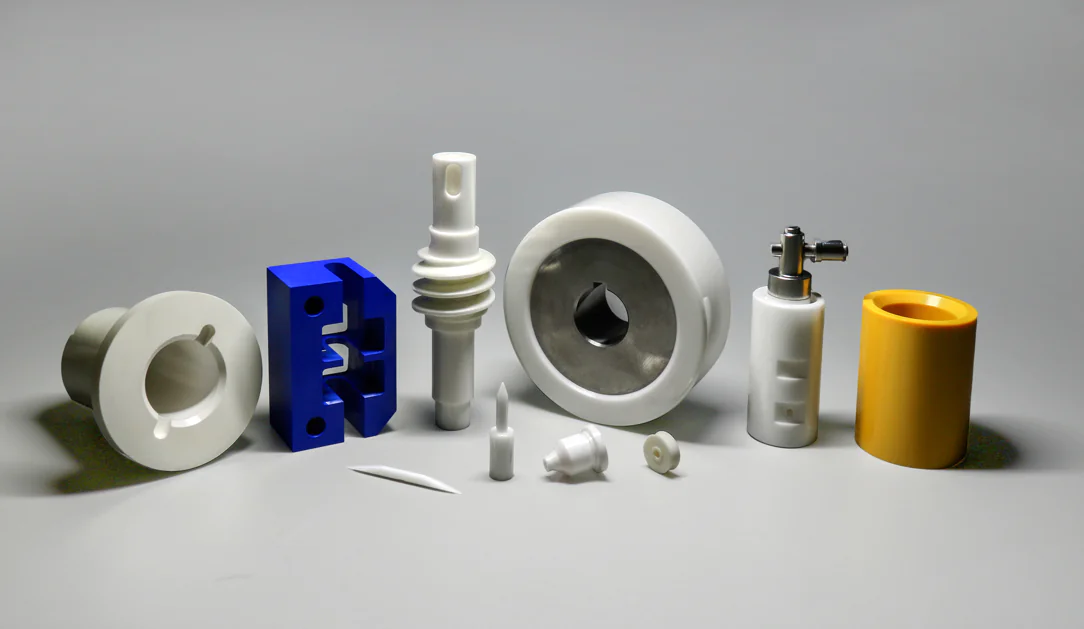

We provide a full range of high-performance ceramic materials and custom-processed components to meet the special requirements of different industries for hardness, wear resistance, high temperature resistance, etc.

Case Overview

Advanced Ceramics

Related Cases

Explore more successful application cases

Ceramic Roller-ceramic Dual-roll-ceramic Three-roll

Precision RollsCeramic Roller-ceramic Dual-roll-ceramic Three-roll 1. Product OverviewTungsten carbide rolls are critical tools used to induce plastic deformation in metals (rolled products). They are essential consumable components that significantly influence mill efficiency and the quality of rolled materials. As core parts of steel rolling mills, these rolls apply pressure through a pair or set of […]

Ceramic pump and valve plunger

Ceramic Valve Plungers and Valve Bodies Ceramic valve plungers and valve bodies are essential components in liquid filling (dispensing) systems. They operate by the reciprocating motion of a piston within a cylinder to aspirate and dispense liquids, relying on precise sealing between the ceramic piston and the piston sleeve. This design enables high-precision metering pumps […]

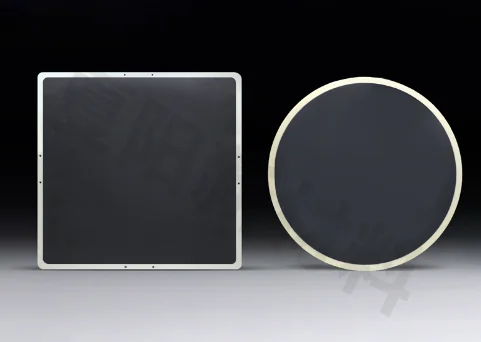

porous suction cup Semiconductor Equipment – Ceramic Vacuum Chuck

Semiconductor Equipment – Ceramic Vacuum Chuck Ceramic vacuum chucks are a special type of vacuum pad made from porous ceramic materials, featuring high porosity, high strength, and excellent surface flatness. They are widely used in semiconductor wafer processes such as slicing, grinding, polishing, and inspection. Product Features ▲ Surface flatness can reach 0.002 mm; parallelism […]

Ready to Start Your Project?

Contact our technical experts to get customized ceramic material solutions

Phone Consultation

+86-769-83939973

Email Contact

mag2@xycarbide.com

Factory Address

No.28, Xiangkou road, Huangnitang District, Changping Town,