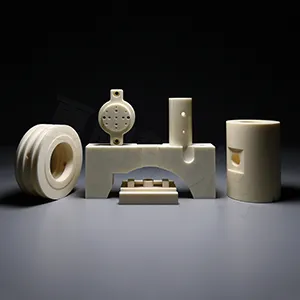

Processing & Material Capabilities

We are equipped with an industry-leading cluster of processing equipment, integrating R&D, sintering, and machining, to ensure 0.005mm-level ultra-precision quality and stable mass production delivery.

Core Processing Equipment

We are equipped with an industry-leading cluster of processing equipment, covering the entire production process of advanced ceramics, to meet the diverse customization needs of global customers:

5-axis CNC machining centers

Realize integrated processing of complex-shaped ceramic components, ensuring high precision and efficiency

Pressure/vacuum sintering furnaces

Adapt to the sintering process requirements of different ceramic materials, improving material density and performance

Optical curve grinding machines

Meet micron-level dimensional accuracy requirements, ensuring the consistency of component sizes

Mirror EDM machines

Guarantee the surface finish of ceramic components, suitable for high-end precision application scenarios

Advanced Materials Portfolio

High-performance Advanced Ceramic & Tungsten Carbide Materials

We provide a full range of high-performance advanced ceramic and tungsten carbide materials, with complete specifications and stable performance, widely used in semiconductor, new energy vehicle, aerospace, medical, and other high-end industries.

당사는 고객 요구 사항에 따라 일부 특수 성능 세라믹을 맞춤 제작할 수 있습니다.

또한 대학 및 연구 기관의 협력도 진심으로 환영합니다.

Toughened Zirconia (ZrO₂)

High wear resistance, excellent insulation, good biocompatibility;

Suitable for new energy vehicle battery insulation parts, medical surgical instruments, food-grade cutting tools.

High-Purity Alumina (Al₂O₃)

High temperature resistance (≤1700℃), strong corrosion resistance, good mechanical strength;

Suitable for semiconductor equipment fixtures, petrochemical corrosion-resistant valves, industrial wear parts.

Silicon Nitride (Si₃N₄)

High strength, excellent thermal shock resistance (-50℃~1200℃), good lubricity;

Suitable for aerospace sensors, new energy vehicle powertrain components, high-speed mechanical parts.

실리콘 카바이드(SiC)

Ultra-high temperature resistance (≤1600℃), high thermal conductivity, strong oxidation resistance;

Suitable for high-power electronic component heat dissipation parts, industrial high-temperature furnace core components, petrochemical equipment.

Aluminum Nitride (AlN)

Excellent electrical insulation, high thermal conductivity (≥180W/m·K);

Suitable for semiconductor chip heat dissipation substrates, 5G communication equipment thermal conductive parts, electronic packaging components.

Tungsten Carbide (WC)

Ultra-high hardness (HRA86~93), excellent wear resistance, high temperature stability (hardness at 500℃);

Suitable for precision cutting tools, petrochemical valves, cold work molds, geological exploration bits, industrial wear-resistant structural parts.

반도체 세라믹 제품 사례

다양한 응용 시나리오의 요구 사항을 충족하기 위해 반도체 산업용으로 개발된 다른 고성능 세라믹 제품을 살펴보세요.

Alumina ceramic wafer chuck with warpage less than 0.05mm, mechanical ceramic arm, handling ceramic arm

High-Precision Alumina Ceramic Components for Advanced Semiconductor Manufacturing 1. Alumina...

자세히 알아보기

Alumina Ceramic Microporous Chuck | Semiconductor Wafer & Chip | Vacuum Chuck | Wear-Resistant Porous Ceramic

Product Description Alumina Ceramic Microporous Chuck | Semiconductor Wafer &...

자세히 알아보기

Silicon nitride ceramic substrate | 6-inch plate CNC processing | Semiconductor

High temperature resistance, acid and alkali corrosion resistance High hardness...

자세히 알아보기문의하기

정밀 기기 재료 또는 맞춤형 요구 사항에 대한 자세한 내용은 아래 양식을 작성해 주시면 전문가 팀이 최대한 빨리 연락드리겠습니다.

회사 주소

중국 광둥성 둥관시 창핑진 황니탕 산업단지 샹커우 로드 28호, 창핑진, 황니탕

연락처 전화

+86-769-83939973

이메일 주소

mag2@xycarbide.com

근무 시간

월~금: 9:00 - 18:00