Precision Tungsten Carbide Solutions

High-performance Tungsten Carbide materials with high hardness, wear resistance, and heat resistance, providing excellent material support for precision manufacturing

Precision Tungsten Carbide (Carbide)

We specialize in the R&D and production of high-performance Tungsten Carbide materials, providing comprehensive material solutions for precision manufacturing, electronics, medical, aerospace and other fields. In recent years, based on our existing wear-resistant series, wear-corrosion-resistant series, high-temperature resistant series, and ultra-fine grain series, XYC has successively developed new materials in non-magnetic series, EDM wire cutting series, and advanced ceramic series.

Tungsten Carbide Definition

Tungsten Carbide, also known as cemented carbide, refers to a sintered composite material containing at least one metal carbide. The grain size of carbide components (or phases) is usually between 0.2-10 microns, and carbide grains are bonded together using a metal binder. The binder is usually cobalt (Co), but for some special purposes, nickel (Ni), iron (Fe) or other metals and alloys can also be used.

Tungsten Carbide

Generally speaking, to improve or use Tungsten Carbide, the following information is required: information about the processed material, processing and forming information, and requirements for the processed product.

Tungsten Carbide Material Advantages

Tungsten Carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance, etc. Especially its high hardness and wear resistance remain basically unchanged even at 500°C, and it still has high hardness at 800°C.

Processed Material Information Requirements:

- Material, composition, performance, shape, surface condition

XYC Tungsten Carbide Product Series

Wear-resistant Series

With extremely high wear resistance and hardness, suitable for manufacturing parts in various wear environments.

Wear-corrosion Resistant Series

Not only has excellent wear resistance, but also has outstanding corrosion resistance, suitable for harsh environments.

High-temperature Resistant Series

Can maintain stable performance in high-temperature environments, suitable for parts working under high-temperature conditions.

Ultra-fine Grain Series

With finer grain size, providing higher hardness and strength, suitable for precision parts.

Non-magnetic Series

Newly developed non-magnetic Tungsten Carbide, suitable for special fields such as high-frequency welding precision instrument parts.

EDM Wire Cutting Series

Manufactured with special elements and processes, reducing binder gasification during EDM processing, improving service life.

Advanced Ceramic Series

Combining ceramic material properties, providing higher hardness and corrosion resistance, suitable for extreme environments.

Custom Series

According to customer special needs, provide customized Tungsten Carbide material solutions to meet different application scenarios.

Special Tungsten Carbide Materials

We have developed various special performance Tungsten Carbide materials to meet the special needs and strict requirements of different industries.

Non-magnetic Tungsten Carbide

Non-magnetic tungsten carbide

Non-magnetic Tungsten Carbide is a magnetic material, commonly used in high-frequency welding precision instrument parts. To meet the needs of specific customers, XYC Company has newly developed W series Tungsten Carbide with hardness ranging from HRA85-91. Its key performance indicators are close to international levels, which can meet the different needs of these customers.

- Excellent non-magnetic properties

- Hardness range: HRA85-91

- Performance indicators close to international levels

- Suitable for high-frequency welding precision instrument parts

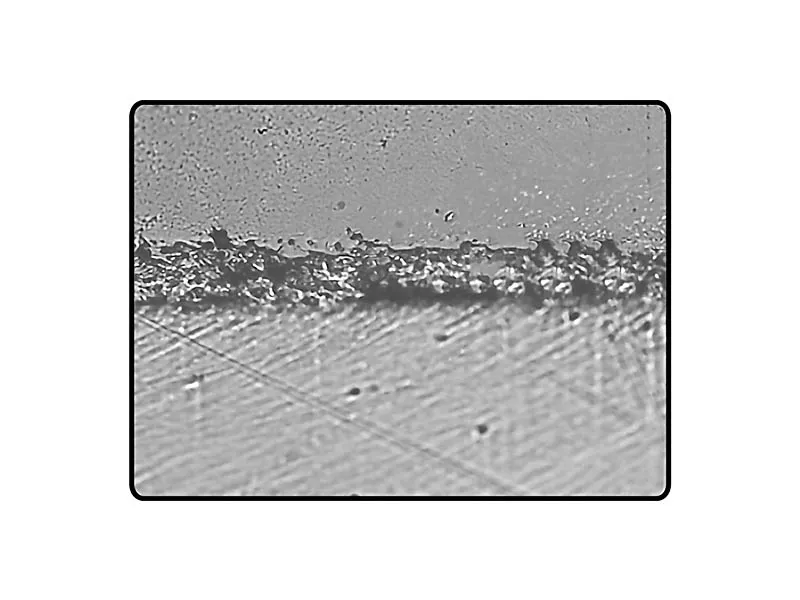

Special Tungsten Carbide for EDM Wire Cutting

Special Tungsten Carbide for EDM and Slow-Speed wire

In the Tungsten Carbide processing process, EDM, wire cutting and other electrical processing equipment are usually used. The instantaneous temperature during EDM processing can reach 8000℃, which causes the binder in Tungsten Carbide to gasify, forming uneven pits on the processed surface, greatly reducing the service life during use. XYC Company has solved this problem through repeated testing by adding special elements and special processes to Tungsten Carbide, which greatly reduces the gasification and melting of the binder during EDM and wire cutting processing. Thus, the service life is increased by more than 50% compared with general Tungsten Carbide, and it can completely replace imported similar products.

- Reduces binder gasification and melting during EDM processing

- Service life is more than 50% longer than general Tungsten Carbide

- Can completely replace imported similar products

- Special element addition and process treatment

- High precision machining performance, meeting ±30°/80mm taper processing requirements

- Excellent dimensional accuracy and surface finish

- Compatible with 5-axis CNC machining systems

Tungsten Carbide Parts

Tungsten Carbide Parts

We provide a variety of Tungsten Carbide parts to meet the special needs and strict requirements of different industries.

Tungsten Carbide Parts Series

Tungsten Carbide Bushing

Tungsten Carbide Rod

Tungsten Carbide Nozzle

Tungsten Carbide Flow Drill

Tungsten Carbide Needle Valve

Tungsten Carbide Valve Core & Sleeve

Tungsten Carbide Molds & Dies

Tungsten Carbide Punch/Pin

Tungsten Carbide Parts Features

Long Service Life

The service life of Tungsten Carbide molds is more than 50 times that of ordinary steel materials

High Precision

High dimensional accuracy, guaranteed quality

Smooth Surface

Good surface finish, excellent product performance

High Cost Performance

High comprehensive cost performance

Tungsten Carbide Rolls

Tungsten carbide Roll

Our tungsten carbide rolls feature high precision, high hardness, high wear resistance and other characteristics, widely used in PV ribbon, FFC wire production and other fields.

| Specifications | Applications | Features |

|---|---|---|

| Φ106*320 |

Special for PV ribbon and FFC wire production Professional used in PV ribbon and pressing metal wire for FFC |

|

XYC rolls have good performance in the market with a large market share. They have been long used with Japanese and domestic first-class rolling equipment, and are deeply trusted and loved by equipment manufacturers and end customers.

Non-magnetic Tungsten Carbide Parts

Non-magnetic tungsten carbide parts

We provide customized non-magnetic Tungsten Carbide parts to meet the non-magnetic requirements of special industries.

Specifications

Customized according to customer drawings

customized according to customer drawings

Features

- Various non-magnetic materials with different hardness are available, or a combination of ordinary steel and non-magnetic Tungsten Carbide can be used

- High precision, long service life, more than 10 times that of ordinary non-magnetic steel

EDM Wire Cutting Special Tungsten Carbide

EDM WEDM Special Tungsten Carbide

EDM wire cutting special Tungsten Carbide material specially designed for precision mold manufacturing and high-demand processing fields, with excellent processing performance and stability.

Technical Parameters

- Adapts to taper processing: ±30°/80mm

- Supports 5-axis 4-linkage processing

- Surface finish up to Ra0.2μm

- Dimensional accuracy ±0.002mm

Application Fields

- Precision mold manufacturing

- Aerospace parts processing

- Medical device parts

- Electronic communication precision parts

Wire Cutting Processing Technology Features

Wire cutting is a high-precision EDM technology. The core difference between it and fast wire cutting is that the copper electrode wire moves in one direction at low speed and is usually discarded after one cut, thus ensuring excellent dimensional accuracy and surface finish.

Our special Tungsten Carbide material has been optimized for this processing technology, with excellent electrical conductivity and thermal stability, which can effectively reduce electrode wire wear and improve processing efficiency and quality.

-

High-precision Processing System

-

Professional Processing Technology System

-

Taper Processing Compensation Function

-

EDM Pulse Discharge Technology

| Category Sorts |

Grade Grade |

HIP | CIP | Grain Grain |

Co(%) | Density Density (g/cm³) |

Hardness HRA |

Hardness HV |

Bending Strength T.R.S (N/mm²) |

Applications Applications |

| Wear-resistant Series Wear-resistant |

M10 | ● | Superfine Superfine |

6 | 14.8 | 94 | 1900 | 3800 | Commonly used for powder metallurgy molds, can also be used for blades and sealing rings | |

| M20 | ● | ● | Medium medium |

6.5 | 14.88 | 91 | 1550 | 3100 | ||

| M30 | ● | ● | Medium medium |

8 | 14.62 | 89.5 | 1400 | 3200 | High hardness, good wear resistance, general drawing mold | |

| M33 | ● | ● | Fine fine |

8 | 14.6 | 92 | 1700 | 3800 | Often used for drawing molds of harder materials | |

| Wear&impact-resistant Series Wear&impact-resistant |

C10 | ● | Medium medium |

10 | 14.3 | 89 | 1200 | 3430 |

Excellent toughness and hardness, good material for common punches, bushings, inserts, also a good choice for forming molds, coiling molds, rolling molds, and drawing molds with high stress Suitable for precision hardware thin sheet stamping, lead frames, IC molds, not suitable for thick sheet stamping Used for various thin sheet stamping, lead frames, LED brackets, IC molds, motor stators and rotors, etc. |

|

| C30 | ● | ● | 中 medium |

15 | 14.2 | 87 | 1070 | 3500 | ||

| C15 | ● | 细 fine |

13 | 14.06 | 91 | 1550 | 3600 | |||

| C35 | ● | 细 fine |

15 | 13.85 | 89.5 | 1320 | 3700 | |||

| C38 | ● | Medium fine Medium fine |

12 | 14.2 | 89 | 1400 | 3300 | Special for silicon steel sheet, EI sheet stamping | ||

| C78 | ● | Fine fine |

12 | 14.1 | 90 | 1450 | 3950 | Special for wire cutting and EDM processing occasions | ||

| C40 | ● | ● | Coarse rough |

20 | 13.6 | 84 | 850 | 2850 | Commonly used for cold stamping, cold heading, cold extrusion molds | |

| C50 | ● | ● | Coarse rough |

22 | 13.4 | 83 | 780 | 2950 | Applied in high stress occasions, such as screws, nuts, forging, etc. | |

| Superfine Grain Series Superfine grade |

QX05 | ● | Ultra-fine superfine |

7 | 14.6 | 94 | 1950 | 3520 | Extremely high hardness, only suitable for wear-resistant parts and tools with low impact force | |

| QX10 | ● | 微 superfine |

8 | 14.6 | 92.8 | 1730 | 3800 | |||

| QX20 | ● | 微 superfine |

10 | 14.45 | 91.8 | 1550 | 4200 | |||

| QX30 | ● | 微 superfine |

12 | 14.15 | 92.3 | 1640 | 4000 | |||

| High-temperature Series Heat resistant |

R20 | ● | Medium medium |

Patent patent |

13 | 83 | 780 | 2550 | Hot forging die | |

| R50 | ● | Medium medium |

Patent patent |

13.2 | 84 | 850 | 2550 | Hot extrusion of small and medium profiles, hot forging die | ||

| Non-magnetic Series Non magnetic |

W10 | ● | ● | Medium medium |

Ni | 14.3 | 89.5 | 1320 | 1500 | Applied to non-magnetic wear parts with low stress |

| W10X | ● | ● | Fine fine |

Ni | 14.3 | 92 | 1760 | 2700 | Commonly used for magnetic forming molds | |

| W30 | ● | ● | Medium medium |

Ni | 14 | 87 | 1160 | 3000 | ||

| W35 | ● | ● | Fine fine |

Ni | 13.8 | 86.5 | 1070 | 2900 | ||

| W40 | ● | ● | Medium medium |

Ni | 13.5 | 85.5 | 930 | 3000 | ||

| The company reserves the right to change the above parameters | ||||||||||

Contact Us

For more information about Tungsten Carbide materials or customized requirements, please fill out the form below, and our professional team will contact you as soon as possible.

Company Address

No. 28, Xiangkou Road, Changping Town, Dongguan City, Guangdong Province, China

Contact Phone

+86-769-83939973

Mobile: +86 18588160018

Email Address

mag2@xycarbide.com

Working Hours

Monday to Friday: 9:00 - 18:00