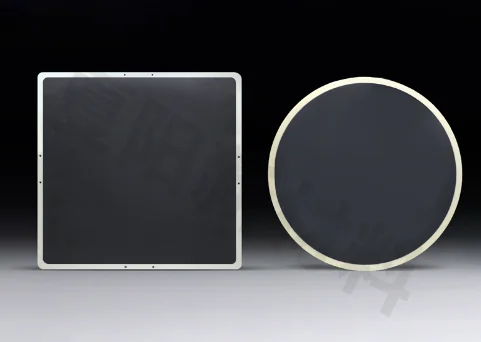

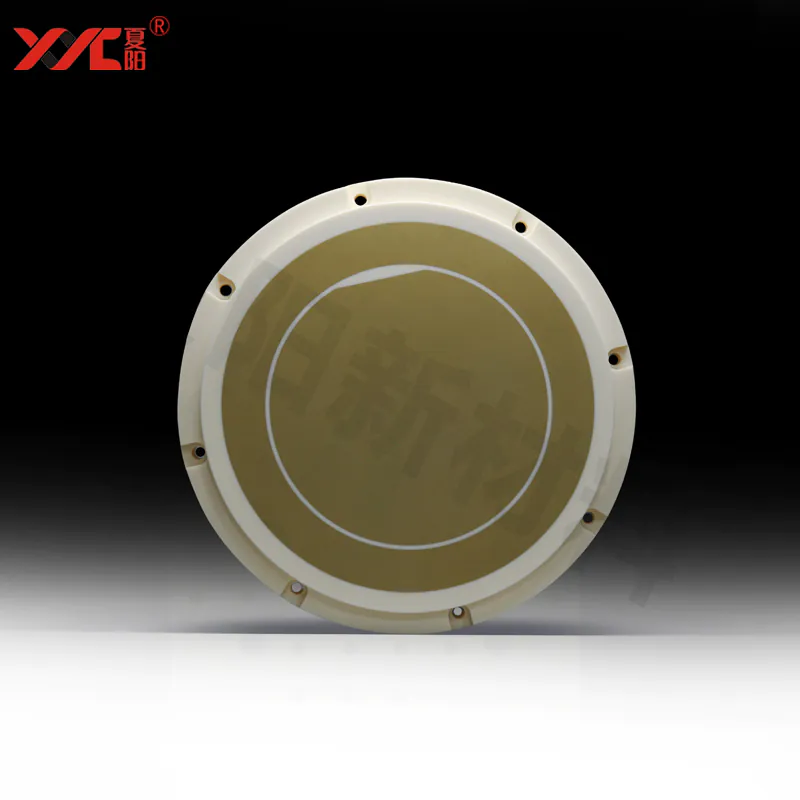

Alumina Ceramic Microporous Chuck | Semiconductor Wafer & Chip | Vacuum Chuck | Wear-Resistant Porous Ceramic

Product Overview

Technical Support & Services

- Provide material selection technical consultation and solutions

- Custom processing according to customer requirements with precision up to ±0.01mm

- Provide product inspection reports and material certification

Product Detailed Specifications

Product Description

Core Advantages

- Uniform Microporous Structure

Uniform pore distribution ensures balanced vacuum adsorption, preventing wafer warpage or slippage during high-speed processing.

- Superior Wear & Corrosion Resistance

Resists mechanical abrasion and chemical corrosion from semiconductor process fluids, extending service life and reducing maintenance costs.

- High-Precision Dimensional Accuracy

Ultra-flat surface and tight tolerance control guarantee seamless compatibility with semiconductor wafers and chips of various specifications.

- Cleanroom Compatibility

Non-contaminating, non-outgassing material properties meet ISO Class 5 cleanroom standards, avoiding particle pollution in semiconductor manufacturing.

Typical Technical Parameters

| Parameter | Specification |

|---|---|

| Material | 99.5%+ High-Purity Alumina (Al₂O₃) |

| Pore Size | 0.5–5 μm (customizable) |

| Porosity | 20–40% (adjustable) |

| Surface Flatness | ≤0.005 mm |

| Hardness | HRA 88–92; Mohs Hardness 9.0 |

| Max Service Temperature | 1200°C |

| Chemical Stability | Resistant to acids, alkalis, plasmas, and semiconductor process chemicals |

| Customizable Sizes | Diameter: 50–500 mm; Thickness: 10–50 mm |

Applications

- Semiconductor wafer handling, dicing, lithography, and etching processes

- Silicon chip packaging and testing equipment

- Flat panel display (FPD) substrate processing

- Optical component manufacturing and precision positioning

Advanced Ceramics

The advanced ceramic family encompasses a variety of materials with distinct properties, each of which has been specially designed for specific application scenarios.

Ceramic Materials

Alumina Ceramics (Al₂O₃)

Alumina is the most widely used advanced ceramic material, offering excellent electrical insulation, high hardness, and good wear resistance. It can operate at temperatures up to 1700°C, making it suitable for a wide range of industrial applications.

Main Application Fields

Widely used in multiple high-end manufacturing fields to provide customized solutions for customers

Ceramic Roller-ceramic Dual-roll-ceramic Three-roll

Precision RollsCeramic Roller-ceramic Dual-roll-ceramic Three-roll 1. Product OverviewTungsten ca...

View Related CasesCeramic pump and valve plunger

Ceramic Valve Plungers and Valve Bodies Ceramic valve plungers and valve bodies are essential...

View Related Casesporous suction cup Semiconductor Equipment – Ceramic Vacuum Chuck

Semiconductor Equipment – Ceramic Vacuum Chuck Ceramic vacuum chucks are a special type of vacuum...

View Related CasesRelated Products Recommendation

You may also be interested in the following products

Silicon Nitride Ceramic Heating Plate | Ceramic Components for Molding Presses

Silicon nitride (Si₃N₄) ceramic heating plates are high-performance structural ceramic components specifically engineered for demanding applications in hot pressing and molding equipment—such as those used in powder metallurgy, technical ceramics, and composite material manufacturing. Leveraging the exceptional properties of silicon nitride, these heating plates deliver outstanding mechanical strength, thermal stability, and electrical insulation even under extreme operating conditions, making them a superior alternative to conventional metal or alumina-based heating elements.

View Details

Alumina Ceramic Microporous Chuck | Semiconductor Wafer & Chip | Vacuum Chuck | Wear-Resistant Porous Ceramic

Product Description Alumina Ceramic Microporous Chuck | Semiconductor Wafer & Chip | Vacuum Chuck | Wear-Resistant Porous Ceramic Crafted from…

View Details

Ceramic mechanical arm / Semiconductor wafer equipment / Handling arm

Ceramic mechanical arm / Semiconductor wafer equipment / Handling arm Excellent wear resistance, high temperature resistance, corrosion resistance, thermal shock resistance,insulation and other characteristics Good price compared with traditional materials, Having strength and fracture toughness that other materials cannot achieve,suitable for highly corrosive and high-strength environments. Green and environmentally friendly

View Details

Ceramic Pump and Valve Plunger

Made of toughened structural ceramic materials, high mechanical strength, long service life With wear resistance, corrosion resistance, high temperature stability,chemical…

View DetailsSend an Inquiry

Contact Us

Why Dongguan XYC New Material Co., Ltd. Is Your Top Choice for Advanced Ceramics

Founded in 2002, Dongguan XYC New Material Co., Ltd. specializes in R&D and production of advanced ceramics and cemented carbides. We have provided precision components (Alumina ceramics(Al₂O₃)、Zirconia ceramics(ZrO₂)、Magnesium-zirconium oxide ceramics (MgO-ZrO₂)、Silicon nitride ceramics(Si₃N₄)、Silicon carbide ceramics(SiC)、Aluminum nitride ceramics(AlN)) to over 2000+ enterprises worldwide, serving industries including semiconductor, automotive, medical, and energy. Here are our core advantages:

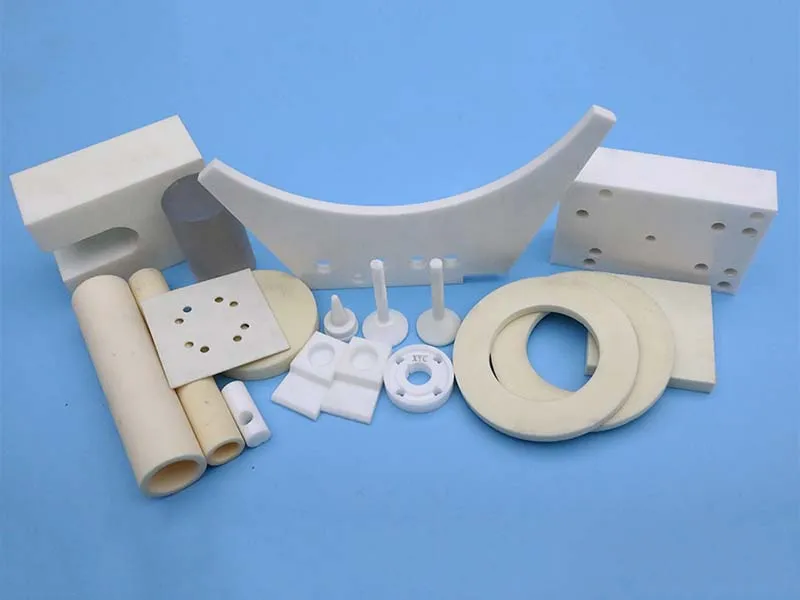

Diverse Materials & Full Product Range

We cover a full range of advanced ceramic materials including Alumina (Al₂O₃), Zirconia (ZrO₂), Silicon Nitride (Si₃N₄), and Silicon Carbide (SiC). We can customize over 10,000+ component forms (tubes, rods, plates, valves, plungers, etc.) to meet material performance requirements across different industries.

High Precision & Extreme Environment Resistance

With precision forming and sintering processes, we achieve ±0.001mm micro-level machining accuracy. Our ceramic components feature high hardness, high temperature resistance (1800°C), strong corrosion resistance, and low friction, making them suitable for extreme working conditions like semiconductor manufacturing and automotive welding.

Cross-Industry Solutions & Customization

We deeply serve industries like semiconductor, automotive, medical, and energy, providing integrated technical solutions from material selection to finished product delivery. We support rapid prototyping for small batches and stable mass production for large orders, meeting customization needs of clients of all scales.