Success Cases

Featured Success Cases

Explore our successful application cases across various industries and learn how XYC Ceramics solves practical problems for customers

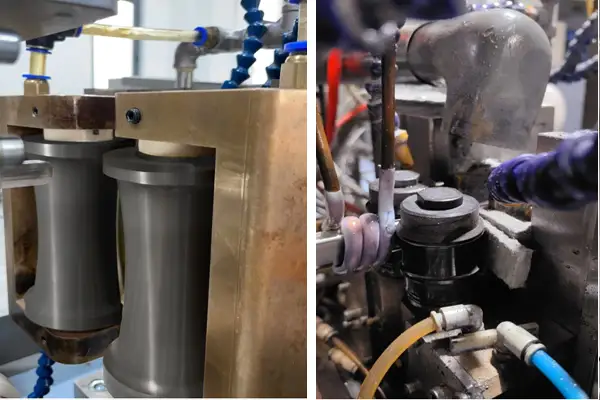

Ceramic Roller-ceramic Dual-roll-ceramic Three-roll

Precision RollsCeramic Roller-ceramic Dual-roll-ceramic Three-roll 1. Product OverviewTungsten carbide rolls are critical tools used to induce plastic deformation in metals (rolled products). They are essential consumable components that significantly influence…

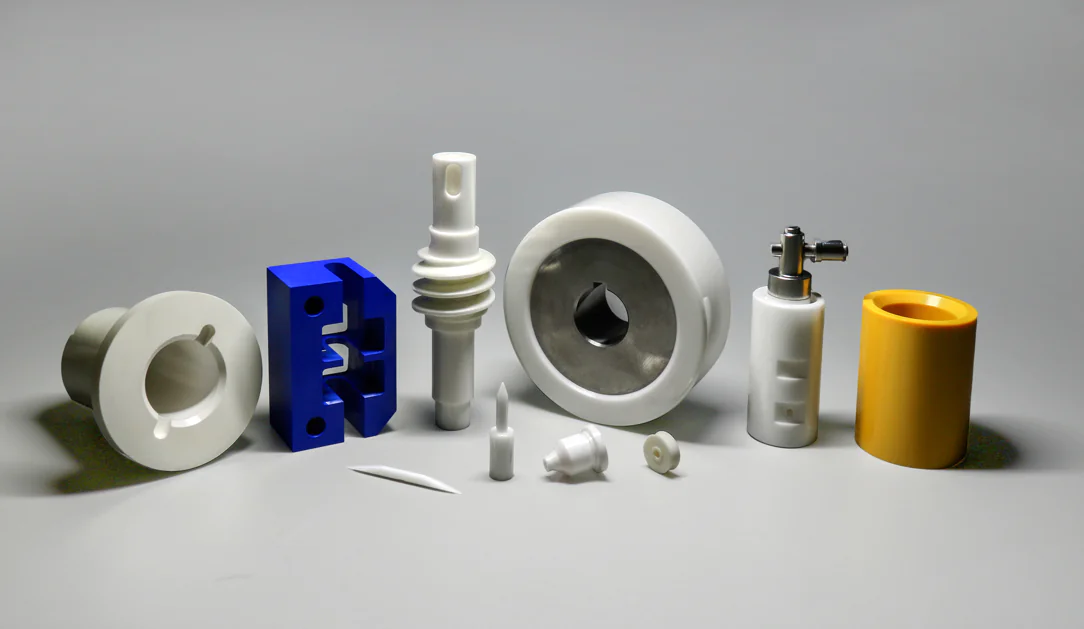

View DetailsCeramic pump and valve plunger

Ceramic Valve Plungers and Valve Bodies Ceramic valve plungers and valve bodies are essential components in liquid filling (dispensing) systems. They operate by the reciprocating motion of a piston within…

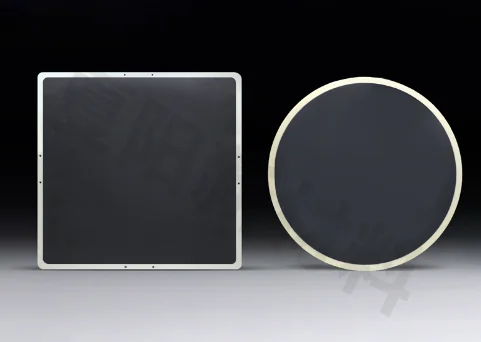

View Detailsporous suction cup Semiconductor Equipment – Ceramic Vacuum Chuck

Semiconductor Equipment – Ceramic Vacuum Chuck Ceramic vacuum chucks are a special type of vacuum pad made from porous ceramic materials, featuring high porosity, high strength, and excellent surface flatness.…

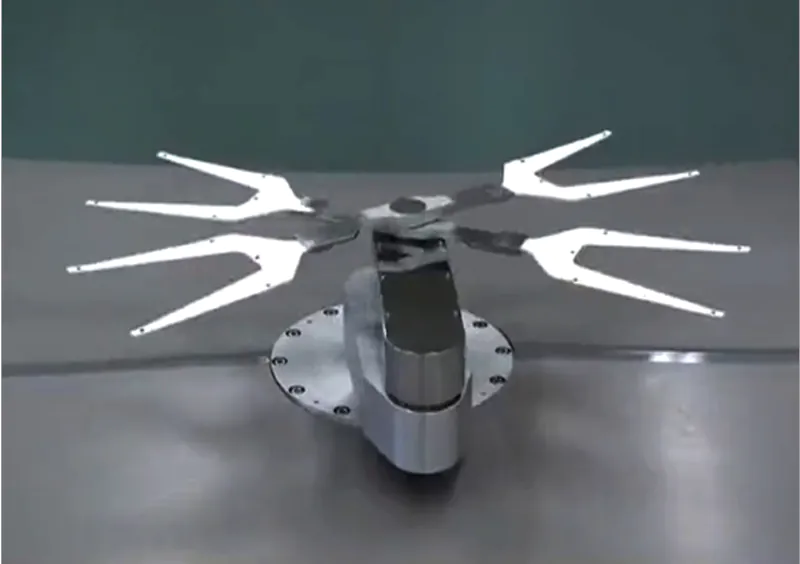

View Detailswafer handling finger

Product Features – Ceramic Robotic Arms for Semiconductor Equipment wafer handling finger Ceramic mechanical arms, also known as ceramic robotic fingers, wafer carriers, or ceramic handling arms, are primarily used…

View DetailsWhy Customers Choose XYC Ceramics

20 years of focus on advanced ceramic R&D and production, providing high-quality ceramic material solutions for customers in various industries

Professional Technical Team

We have a professional R&D team composed of materials science doctors and senior engineers, continuously driving technological innovation

Advanced Production Equipment

We have introduced advanced ceramic production and testing equipment from home and abroad to ensure stable and reliable product quality

Comprehensive Quality Management

We strictly implement the ISO9001 quality management system, and our products have passed multiple international certifications, ensuring quality

Customized Services

We provide customized solutions according to customer needs, with full technical support from material selection to product processing

Success Cases

With professional technical capabilities and high-quality product solutions, we have served 2000+ customers in 30+ countries and regions, and accumulated rich industry application experience. Below are typical cases of XYC ceramics empowering high-end industries:

Semiconductor Industry

We have cooperated with Top 5 global semiconductor equipment manufacturers, providing customized aluminum nitride heat dissipation substrates and high-purity alumina fixtures. These products effectively solve the problem of heat accumulation in chip processing, increasing heat dissipation efficiency by 30% and production line yield by 15%, and have been highly recognized by customers for their stable performance.

Aluminum Nitride Substrate in Semiconductor Equipment

Zirconia Insulation Parts in BYD Battery System

New Energy Vehicle Industry

As a cooperative partner of BYD, we provide zirconia insulation parts and silicon nitride powertrain components for its new energy vehicle battery systems. After strict testing, the products have passed 1000+ charge-discharge cycle tests with 0 failure rate, effectively improving the safety and service life of the battery system.

Industrial Equipment Industry

We have delivered silicon carbide high-temperature components to a leading domestic industrial furnace enterprise. These components can withstand continuous operation under 1600℃ high-temperature working conditions, with good thermal shock resistance and corrosion resistance, doubling the service life of the original components and reducing the customer's production and maintenance costs.

Silicon Carbide Components in 1600℃ Industrial Furnace

Zirconia Plunger in Medical Dialysis Pump

Medical Industry

Our toughened zirconia surgical instruments have passed medical-grade biocompatibility certification, with smooth surface, high wear resistance, and no metal contamination. They have been adopted by more than 30 Grade A tertiary hospitals in China, effectively improving the safety and efficiency of surgical operations.

Customer Reviews

Listen to what our customers say

"The ceramic components for semiconductor equipment provided by XYC Ceramics have stable quality and long service life, effectively improving the reliability and production efficiency of our equipment. We are deeply impressed by the professional technical team and perfect after-sales service."

Chief Engineer Zhang

A Semiconductor Equipment Manufacturer

"As a new energy vehicle parts supplier, we pay great attention to product safety and reliability. The insulated ceramic components from XYC Ceramics fully meet our high requirements, with timely delivery and pleasant cooperation."

Purchasing Manager Li

A New Energy Vehicle Parts Enterprise

"The ceramic components for medical equipment developed by XYC Ceramics not only meet the biocompatibility requirements but also provide good processing precision, greatly improving the performance of our products. Their professional technical support made the entire cooperation process very smooth."

R&D Director Wang

A Medical Device Technology Company

Need Customized Ceramic Solutions?

No matter which industry you are in, we can provide you with professional ceramic material solutions, please feel free to contact us anytime

Consult Now